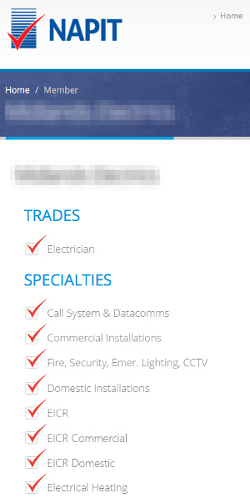

Oh.. my.. goodness. And to make matters worse, this guy is apparently a member of NAPIT, the same as me!

I was recently called out to perform an electrical inspection on a house that had been refurbished following a fire. The homeowner had a loft conversion installed in 2012 but a faulty computer subsequently located in the new room caused the conflagration which gutted the roof space. Besides that, smoke damage and cascading water from the firefighting effort had left the lower rooms ruined.

The insurance company subsequently appointed a builder to make good and the builder subbied out a NAPIT registered sparkie for the wiring work. All was supposedly put right in 2013, although the homeowner tells me she expressed concerns about the quality of the electrical work at the time which even to her untrained eye didn’t look like it was being installed professionally. She was reassured by the builder that the electrical contractor was fully accredited and knew what he was doing.

In 2014 she was visited by Rob of Smart Electrics who, at the time, ran a reputable one-man-band operation here in Leamington under his Elecsa umbrella. The homeowner wanted Rob to undertake a small electrical job, however while there Rob saw for himself some issues which raised a quizzical eyebrow or three. Rob spotted wiring had been spurred in 1mm2 cable from the socket ring to serve two twin socket outlets. This is a regulation no-no as 1mm2 cable is too thin without protection by a fuse, none such being present here, and besides, the regs state that 1.5mm2 is a minimum for power circuits (table 52.3). Not only that, but the socket ring which was otherwise wired in 2.5mm2 wiring was being ‘protected’ by a 40A breaker and not the 32A type which would be correct as a maximum for that size of cabling in a ring configuration. Seeing as a dryer had been plugged in to one of these sockets along with other appliances, the thinner spur cable could easily have overloaded and itself burned without the protective device ever operating.

Rob also found that where the 1mm2 wiring had been spurred into the ring cabling, it had been done without an enclosure, fuse or strain relief. The junction had been left exposed with basic insulation accessible and live brass buzzing away uncovered. He took the picture below.

1mm cable junctioned into 2.5mm cable via screw terminals without an enclosure, a fuse,

strain relief or any thought to professional standards.

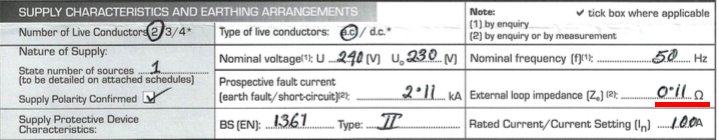

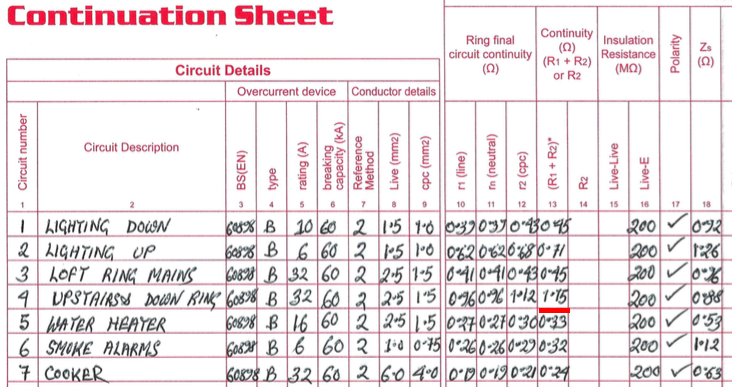

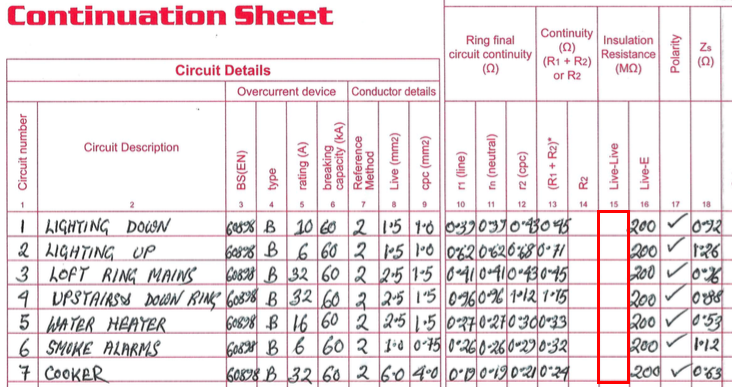

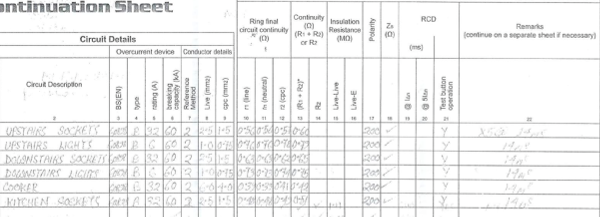

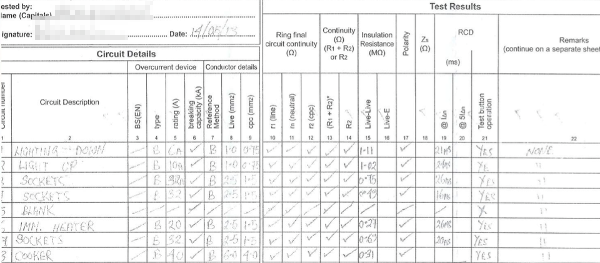

Rob also noticed that the Electrical Installation Certificate (EIC) provided by the electrician didn’t match the layout of the new consumer unit which had been installed as part of the remedial work. Rob recommended at the time that the homeowner have a full Electrical Installation Condition Report (EICR) commissioned to check over the entire installation and that she complain to NAPIT about the quality of the work of this particular installer who was operating under their registration scheme.

The layout of this EIC Schedule in no way matches the layout of the consumer unit, but that's just part of the problem as we shall see.

The homeowner put it out of head for whatever reason, so fast forward to early 2016 and she decides it’s time to dig into her purse and get that EICR underway. Rob is no longer working on the tools, so he sends her my way and I visit site in late January to perform said inspection.

What I found there was a standard of work I’ve never seen before from a so-called professional who holds accreditation. Yes, it’s bad, yes it’s dangerous, but at the same time there’s a level of pure buffonery here that I haven’t experienced on any previous installation by someone who is supposed to know his trade.

So, let’s roll up our sleeves and take a look at just what is setting off the alarm bells on this stinker…

First up, Rob was quite right, and as you can see from the previous picture, the Schedule of Test Results on the EIC does not match the layout of the consumer unit. How can someone who installs and certifies a new CU balls-up something as basic as listing the circuits in order? Even the circuits named on the EIC aren't right, for example the kitchen has a socket ring of its own which isn't listed on the Schedule at all. Besides that, smoke alarms and upstairs lighting are shown as separate circuits when they’re actually all connected together. "Water heater" makes you assume this relates to an immersion appliance, but that’s spurred off the socket ring in the loft and the water heater circuit actually only supplies power to the central heating unit in the kitchen.

Straight away I have issues with these arrangements. It’s not ideal that the smoke alarms share the lighting because they’re a safety circuit and should be segregated so that if the lighting fails for whatever reason then it doesn’t go knocking off power to the smokes. This is where Regulation 314 (division of installation) comes in to play. Hanging smoke detectors off lights isn't wrong, but why has it been done in this way here? Regarding the water heater, Appendix 15 advises loads of over 2kW to be on their own dedicated circuit and not be spurred from the sockets, so what is a 3kW immersion heater doing hanging off the new attic room circuit?

What you have to remember is that this property has been stripped out and this guy has been appointed to install a new consumer unit and new wiring as required, so he has the opportunity to install whatever circuits are needed. Ceilings are down, everything has to be re-plastered so there’s no reason for any shortcuts.

Seeing as the place had been wrecked by fire, you’d assume that the builder and sparky would be conscious of the effect that would have had on the folks living here and they would want to ensure a repeat incident couldn’t happen. As they’re taking the opportunity of installing downlights into all the new ceilings that are going in, they should use downlight models rated to Part-B of the Building Regulations (Fire Safety). Fire rated downlights have an enclosed can with an intumescent seal that melts in excessive heat and maintains the natural fire rating of a plasterboard ceiling, meaning it can take up to 90 minutes for that fire to break through into the cavity and rooms above. Fire rated lights should be used whenever there is an occupied floor above. In this case, the homeowner has been charged for fire rated lights, it says so on the builder’s invoice, however open-backed non-fire rated tat has been bunged up instead. A fire in a lower room would break through such lights in no time at all and spread to the upper floors. Not only that, but as you can see from the picture below, they’re not even terminated correctly as the outer sheaths of the cables should enter the strain relief of the connection enclosure and no basic insulation, (brown, blue & green/yellow), should be on show.

Cheap open-backed non-fire rated and improperly terminated downlights.

A quality downlight will allow for two cables to enter the cord grip and for somewhere to terminate the CPC even if it’s double-insulated and no earth is required. A cheap downlight like these will only accommodate a 2-core flex, so an external junction box should be employed to terminate the incoming/outgoing twin & earth plus flex. A poor installation will see just what we have here, a cheap non-fire rated DIY store downlight which isn’t designed to accommodate two twin & earth cables, so a lazy installer simply whacks in the inner cores leaving one layer of insulation removed and no adequate strain relief. As for the earth, on some of the downlights in this installation he'd just lopped ‘em together into a bit of sleeving with no mechanical means of connection at all (i.e. no crimp, screw terminal, push fit connector or anything else).

This has already led to another near-miss fire incident. When I arrived, I was shown lighting in the en-suite which, when activated, resulted in an arc above the ceiling that was only squashed by the 10A MCB protecting the circuit. And here’s why…

A near miss second fire incident.

This is a connector for one of the non-fire rated and incorrectly terminated downlights. I suspect it has overheated because the wiring and connector enclosure have been in direct contact with the rear of the halogen lamp as the installer neglected to fit the metal stand-offs designed to keep the wiring out of the way. As a result, the cable has melted and shorted causing it to go bang whenever switched on. If that breaker had failed to operate, or if it had been of a higher value like the one Rob found had been incorrectly installed for the sockets, then there could have been a second fire at the property.

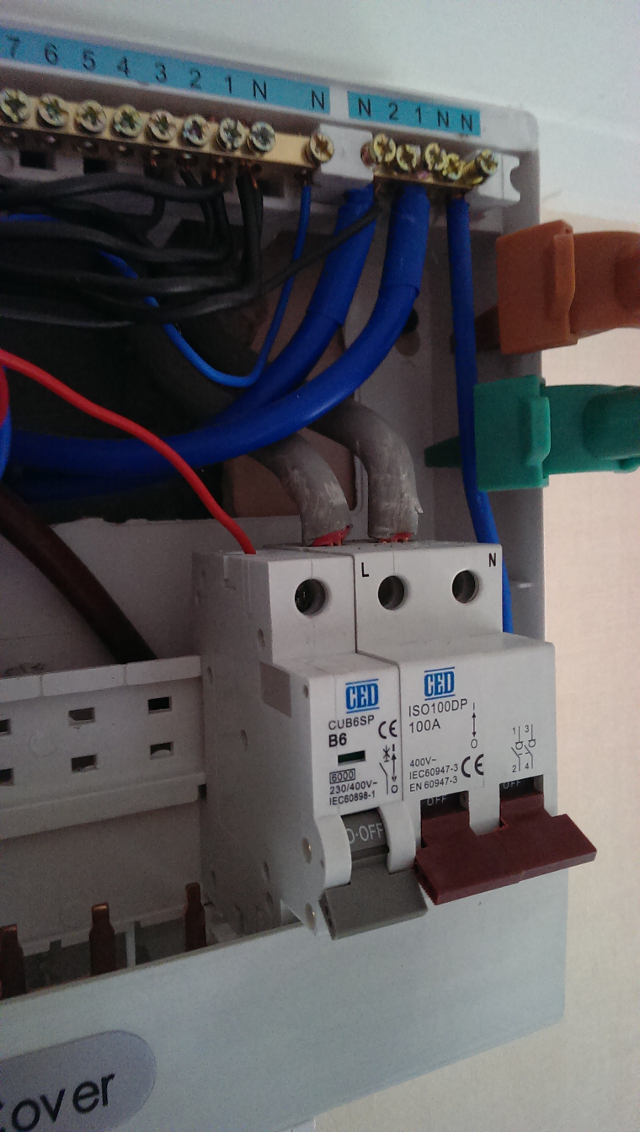

Let’s take a closer look at how he has laid out the budget consumer unit he’s installed.

This is a dual RCD board and so long as there are no faults on the final circuits, which presumably he has tested in full and rewired or repaired if needed, then each of those circuits can sit on one of the RCD’s. This is advantageous as an RCD is there to protect you from electric shock. On a simplified level, any circuit serving or passing through a room with a bath or shower, with wiring buried in the wall at less than 50mm, serving mobile equipment outdoors or serving socket outlets should be RCD protected if installed to the 17th Edition of the wiring regulations. As this work was performed in 2013, BS7671 17th Addition up to Amendment 2 applies.

So, that being the case, what on earth is the downstairs lighting doing off the RCD?

Lighting MCB not on an RCD.

It’s not like there isn’t room to accommodate this circuit; both RCD’s have spare capacity on their busbars and when I tested this circuit in 2016 there were no earth or insulation resistance faults on the lights that might cause a trip. With metal light switches, cables in walls at less than 50mm and metal light fittings, having the circuit covered by a device which will prevent electric shock in the event of a fault is great, so why leave it out? Seeing as the outer insulation on every downlight fitting has been compromised and earth tails hadn't been installed on some of the metal switches, I’d say it’s especially important for a circuit like that to be moved onto an RCD!

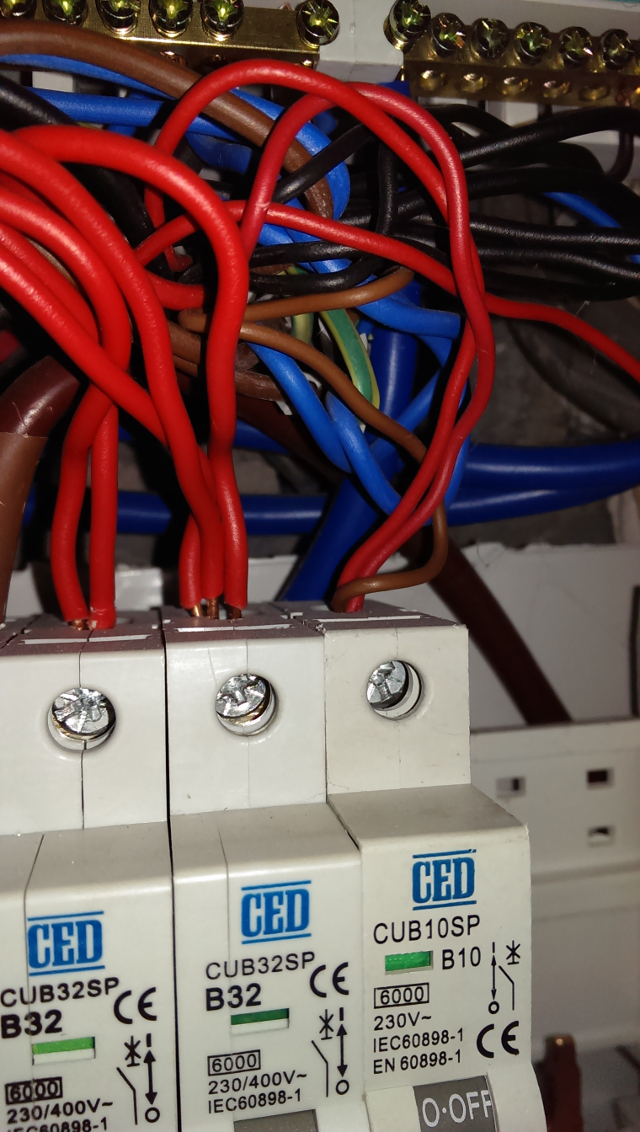

But check out this effort. There are three things wrong in the following picture besides the general mess…

1. I spy a 32A MCB with three 2.5mm wires entering it. Two are the ends of a socket ring and are valid, but the third is presumably a radial circuit going somewhere else. I say presumably because his paperwork doesn’t indicate what this cable might be serving. Whatever it is though, a 2.5mm cable is rated at between 17.5A to 30A depending on how it’s installed so a 32A breaker will not protect it unless it’s in a ring configuration. As it turned out, I couldn’t find what the cable was doing so I left it disconnected. To date, nothing has cropped up that isn’t working, so presumably it’s redundant, perhaps relating to the pre-fire installation. If it isn’t doing anything, how did matey not spot it and why did he hook it into a breaker that couldn’t protect it?

Another reason for leaving this cable disconnected was because its neutral wire was connected to the neutral bar of the opposite RCD, so if a load was ever pulled through it then there would have been a trip event.

2. There are three 1mm wires going into that 10A MCB on the right. My original assumption was that the two red (old colour) cables each serviced the original first floor lighting and smoke alarms and that the brown (new colour) cable would be for the new lighting circuit in the attic conversion, and I suspect that’s exactly what they’re supposed to be, however it turns out to be a little different today. One red wire does nothing. Again, why is it connected? Surely he should have known what it used to to? Why connect and energise a cable where the endpoint is unknown? As for the other red and the brown wires, well they do everything else. That is to say, disconnect one and it makes no difference so long as the other is connected. He’s gone to the effort of installing a new lighting circuit in the loft conversion and bringing the cable all the way down to the CU at the ground floor, but he's cross connected it somewhere into the original first floor lighting. Same with the smoke alarms which were probably also independent once. This means if you disconnect one wire, the first floor lighting, second floor lighting and the smoke alarms all remain powered, as does the disconnected cable. This borks Regulation 314 (division of installation), as a fault on the first floor lights will not only knock out the second floor lights, but also the smoke alarms (or vice versa in any combination). This is worse than when the property was originally wired as the lights and smokes were probably originally separate, but he’s somehow managed to mash them all together with each other *and* with the new second floor lighting.

3. Just why are those lights hanging off a 10A breaker anyway? Going back to an earlier point, Rob’s theory on why this installer had hung a socket ring off a 40A breaker was because he’d bought a fully-loaded consumer unit and found he was short of a 32A MCB so he used what was available. That doesn’t hold water with me. The reason I beg to differ is because the hob is hanging off a 40A MCB and you usually only get one 40A breaker in a fully loaded domestic CU, however you get up to four 32A MCB’s in a loaded CU this size to cover socket rings and cooking appliances. What you don’t get are 10A MCB’s as standard, and you can see that this one doesn’t physically match its neighbours, so it couldn’t have been supplied as part of a factory-loaded board. This means he must have gone out of his way to source additional MCB's. With 1mm2 cable and derating factors likely to apply, that should be a 6A MCB on the lighting. The reason it is a 10A breaker is because of all the halogen downlights hanging off it, which for the first and second floor combined could add up to more than 6A, but had he left the first and second floor lighting independent of each other then he could have used the correctly sized breakers for the job.

This is where things get really special though. Look what I found behind a bathroom downlight…

Ouch! Seriously, does this look like a professional electrical junction you’d expect from a member of NAPIT? Believe it or not, it gets worse when you remove the electrical tape:

Oh yes. Not even a choc-block screw connector. He has merely wrapped the wires together before covering them with tape. This isn’t just bad workmanship, this isn’t just being cheap, this is a level of lazy ineptitude I’ve never seen from an accredited installer before. Are we really to believe he turned up to perform a partial rewire, which presumably took several days, but failed to put basic items such as junction boxes on the van?

Okay, so we’ve found plenty of serious faults with his tool-work, from underprotected wiring to cross-connected circuits to inadequate terminations, but we haven’t even begun to pick the peanuts out of his paperwork yet; and yes, he did supply an Electrical Installation Certificate for this nonsense with his signature on it to accept the legal liability for the electrical safety, so let's grab a fork and pick through this turd...

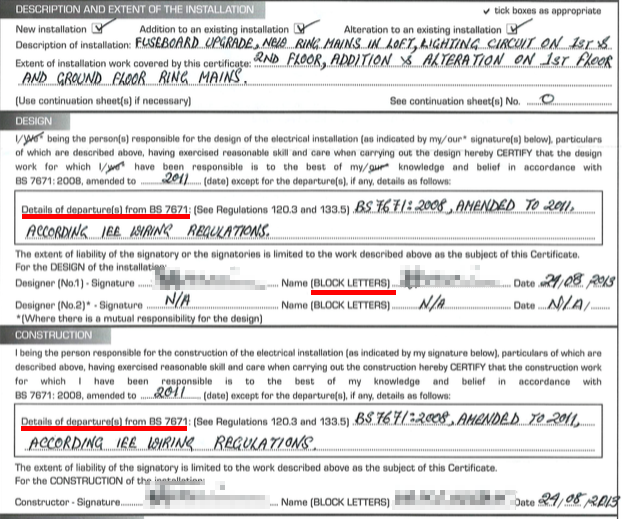

You can see what he’s admitted to doing as this EIC covers “fuseboard upgrade, new ring mains in loft, lighting circuit on 1st & 2nd floor, addition & alteration on 1st and ground floor ring mains’. We know he’s done more as all the ceilings were replaced so why is there no mention of the ground floor lighting alterations for example?

He doesn’t seem to recognise that the ‘details of departures’ boxes are where you list why you’ve departed from the wiring regs, if indeed you have, but he seems to believe somehow that he hasn’t. Obscured here is the fact that he has his signature and name the wrong way around which you may think is me being pedantic, but if he's used to filling out certificates then simple things like this shouldn't be catching him off-guard.

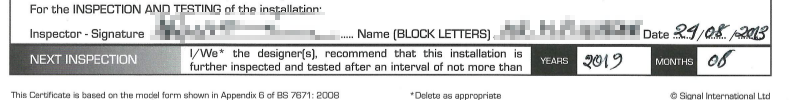

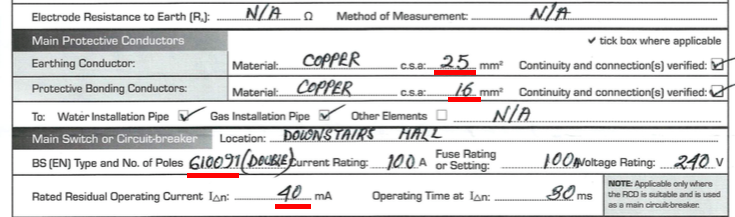

Let’s just check the dates though, as we have a sign-off date of 24/08/13 and a Next Inspection date of August 2019 on the cert.

That’s backed up later on in the certificate here:

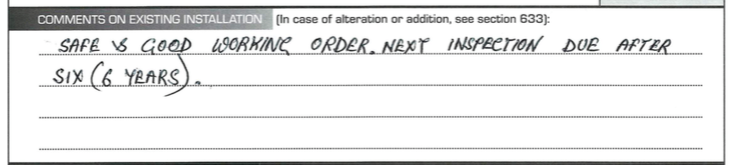

So that being the case, how come the associated inspection sticker affixed to the CU is dated 14/05/13 with a Next Inspection date of 13/05/15?

If he’s making good a gutted property, repairing what’s damaged and rewiring what’s not repairable, how come he’s only signing it off for two years on the sticker or six years on the cert? If he’s done his job properly, then that electrical installation should be in tip-top condition once finished and it should be fit for the maximum sign-off of ten years.

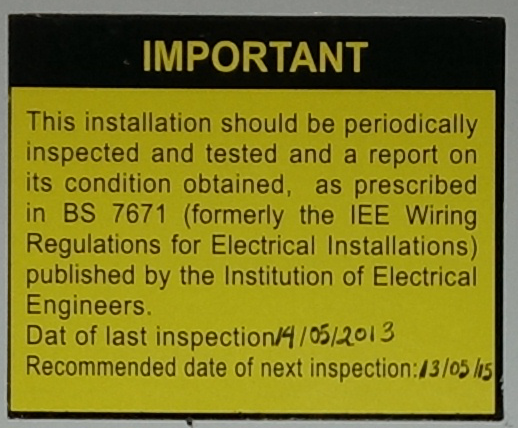

Look at these next schoolboy errors though. Main earthing 25mm2? No matey, the main earthing on this TNC-S installation is 16mm2. Protective bonding conductors 16mm2? Nope, ten millimetres actually. A professional should be able to recognise a common cable cross-sectional-area simply by looking at it, but as most modern domestic TNC-S installations such as this are 16/10 (at least 99% of the ones I’ve seen in Warwickshire), then if you do come across a 25/16 it should stand out as being unusual. It’s not the case here however.

Anyone ever come across a 40mA RCD? Me neither.

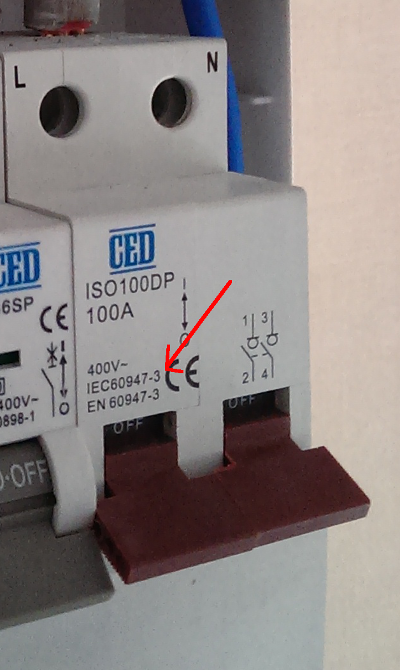

As for the BS(EN) number of the main switch, 610091 is not a valid number. BS(EN)61009 is valid for an RCBO, but this CU has a main switch to BS(EN)60947-3 as you would expect. The damn number is written on the thing, twice in fact.

Let’s move on to the Schedule of Inspections…

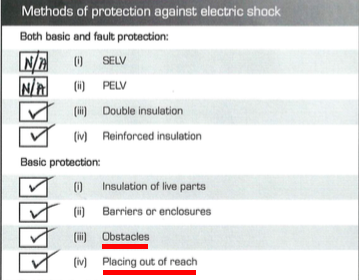

He’s ticked Obstacles and Placing out of Reach as methods of protection against electric shock. Let’s check what Regulation 417 has to say about that…

“The protective measures of obstacles and placing out of reach provide basic protection only. They are for application in installations, with or without fault protection, that are controlled or supervised by skilled persons.”

That is to say, in a four bedroom semi-detached, these methods of protection cannot apply. You can't rely on the electrics in a domestic installation being under supervised, skilled control, so why has he ticked the boxes? What obstacles does he think he’s installed in this house which prevents access to live parts? What has he placed in a troublesome location or sufficient height that it cannot be accessed in a deliberate manner or without specialist equipment? Does he think this should be ticked simply because he’s installed the consumer unit 180cm up the wall? Regulation 417.3.1 states that bare live parts shall not be in arms reach, so a consumer unit at head height wouldn't count. What else could this refer to though?

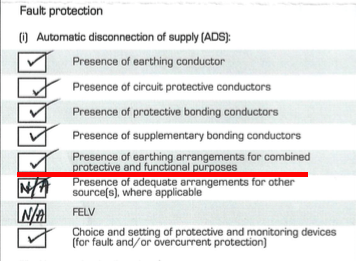

Here’s another one. Presence of earthing arrangements for combined protective and functional purposes.

So... where are the functional earths in this house? Is this an I.T. suite requiring a clean earth? No, it’s a domestic property and the earths here are for protective purposes only.

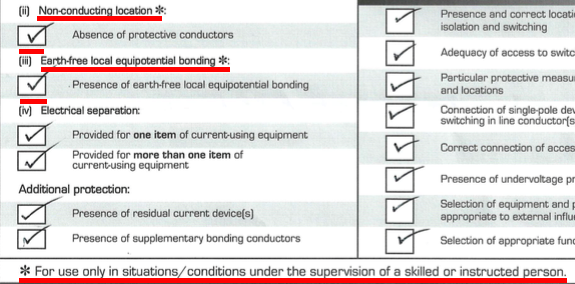

Next, he’s ticked Absence of Protective Conductors for a Non-Conducting Location and he’s ticked Presence of earth-free Local Equipotential Bonding, but his own form even specifies that these boxes only relate to situations/conditions under the supervision of a skilled or instructed person, so how does he think either fit in with a domestic installation?

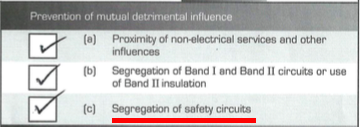

Here’s one we covered earlier, Segregation of Safety Circuits. It’s ticked, but we already know he’s mashed the smoke alarms in with the first floor and second floor lights.

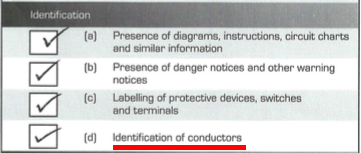

Hm. Identification of conductors huh?

Okay, let’s just remind ourselves of that junction above the bathroom ceiling…

What I see here is a black wire in amongst some blue wires, so I guess that’s a neutral, but also a grey wire and a blue wire in amongst brown wires, so I guess they’re switched lines? None of them are sleeved though, and it’s the same behind light switches where blue cores are used as switched lines, so that seems to blow a hole in his identification of conductors. If you’re changing the function of a particular coloured core then you're supposed to colour code it with sleeving or tape to identify what it's really doing.

We'll take these next three underlined tick-boxes in order...

…no… no, and thrice, no.

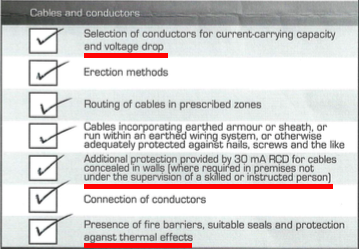

I’ve already described his undersized wiring and oversized breaker larks, so Selection of Conductors for Current-Carrying Capacity is fully sunk. Additional protection by an RCD for cables concealed in walls? Well, yes, except for the ground floor lighting which he needlessly left off the RCD. As for protection against thermal effects, I refer you again to the near-miss fire caused by his cack-handed downlight installation.

The final part of the installation checklist:

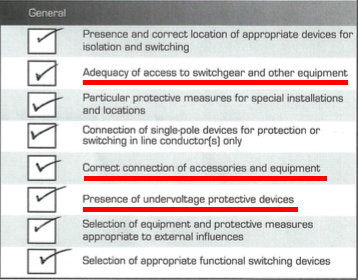

I’ve underlined Adequacy of Access to Switchgear and Other Equipment because he’s ticked it and that raises a possible contradiction from earlier. Presuming he earlier ticked Placing out of Reach because the consumer unit was 1.8m up the wall and therefore kind of inaccessible to children, stating now that the switchgear *is* accessible doesn't fit.

Correct connection of accessories and equipment? Well pick any downlight and you’ll see that’s not the case. As for Presence of Undervoltage Protective Devices, that usually relates to motors or rotating/moving machinery and applies to things like DOL starters. You’ll see that kind of equipment in a factory, not a 4-bedroom semi, at least, not unless it’s equipped with a pretty doozy workshop or industrial kitchen appliances. It certainly doesn’t apply in this case.

Finally, we come to the Schedule of Test Results. Here’s where he has supposedly performed the appropriate testing on all the final circuits, and I do mean all the circuits because he’s replacing the consumer unit, so he is changing the protective devices for the whole installation. That being the case, he’d better be sure his numbers are correct.

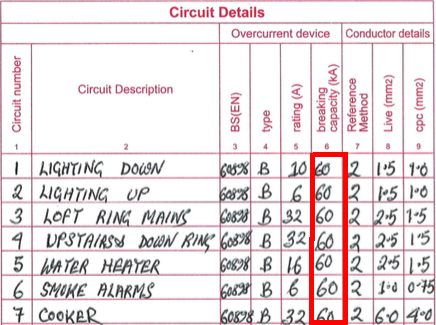

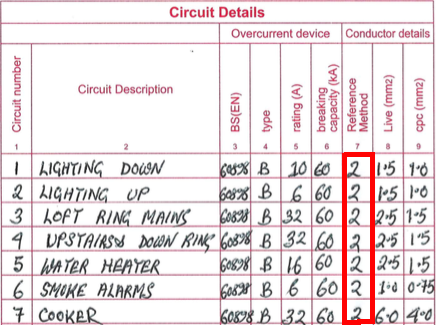

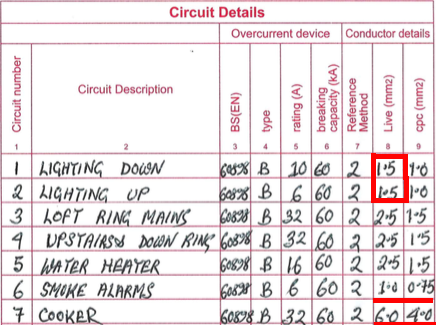

We already know his Schedule of Inspections doesn’t match the circuit layout of the consumer unit he’s installed, but let’s look at what he’s filled in on the form…

First up, a breaking capacity of 60kA per device? These are cheap CED brand MCB’s which, at the time of writing, cost £1.78 each with VAT at Toolstation. Frankly, I’m surprised you can even buy a breaker that’s genuinely compatible with British Standards for so little, but no my friends, these MCB’s are rated at 6kA like most other domestic Type-B MCB’s. A domestic TNC-S shouldn’t exceed a fault current of 16kA and you’ll pay through the nose for an industrial rated breaker above 10kA, so this is clearly a silly mistake on the form. But a member of the National Association of Professional Inspectors and Testers making such a basic error?? Unimaginable.

Move one column to the right and we’re presented with Reference Method 2 for all circuits. What the hell is Reference Method 2? BS7671 lists methods A, B, C, D, E, F, G, 100, 101, 102, 103… and.. uh… well, if there is a reference method 2, I can’t find it and it certainly never applied anywhere on this installation.

Alarm bells are ringing on this next one because the lighting cables he’s listed at 1.5mm2 are clearly 1mm2 to the trained eye, but also because he has the smoke alarms on 1.0/0.75mm2 cable and such a cable doesn’t exist – 1/1 is the lowest size you’ll find for twin and earth. Also the cooker wiring he has listed as 6/4mm2 instead of 6/2.5mm2 which is the actual size of the twin & earth you’ll get over the counter from any electrical wholesaler.

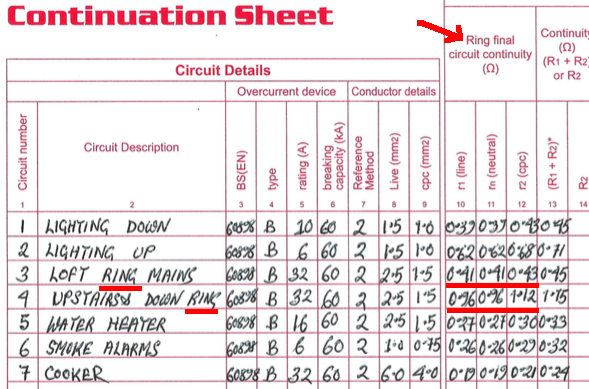

We’re in full-on nonsense territory with the above. Notice the header which says ‘Ring final circuit continuity’? Well, the r1, rn and r2 columns below that should list the resistance values for a socket ring on an end-to-end continuity test. Only circuits 3 & 4 are rings, at least on this list, everything else is a radial circuit, so only circuits 3 & 4 should have values in these columns. Values recorded for all other circuits under r1, rn and r2 are therefore meaningless. What are they supposed to represent here? Are we seriously to believe that this guy was so diligent that he measured the resistance of each core of each cable from end to end? We know he’s not diligent because we can see he wire wrapped & taped junctions and he can’t be arsed to properly terminate downlights. Besides, take circuit 5, 'water heater'; he says it’s a 2.5/1.5 cable so in a perfect world the resistance of the 1.5mm2 core should be 1.67 times higher than that of the 2.5mm2 core as it is 1.67 times thinner (2.5 / 1.67 = 1.5). He has recorded 0.27 Ohm each for r1 (line) and rn (neutral), so r2 (earth) should ideally be 0.27 x 1.67 = 0.451 Ohm, but he’s recorded 0.30 Ohm so it can’t be an end to end test as it doesn’t come close to adding up. In fact, none of these numbers add up. Take Loft Ring Main – this is one of the new circuits he himself has installed, but he has r1 and rn at 0.41 Ohm each and r2 just 0.02 Ohm higher at 0.43 Ohm. That r2 should be 0.41 x 1.67 = 0.685 Ohm so the maths proves that something is wrong as r2 cannot physically be just 0.02 Ohms higher on a new circuit which he admits to installing in 2.5/1.5mm2 cable unless he's spliced it into a parallel path such as a copper water pipe or another circuit's protective conductor which has lowered the resistance. If that’s truly the result he’s getting, then he’s either not doing the test right or it's a miswire. The fucking doughnut has recorded these numbers as though they're acceptable when they cannot be correct.

Earlier on in the cert, he stated that he measured the external Earth Fault Loop Impedance (Ze) as 0.11 Ohm.

Now remember he said that; it’s there in black and white. Any proper spark can tell you that the sum impedance of any final circuit (the Zs) is made up of the Ze (external impedance) added to the R1+R2 (line + earth impedance) of the circuit. So, with that in mind, what’s happening on circuit 4?

R1+R2, the impedance of the circuit, is given as 1.15 Ohm. This may be an issue as the circuit is protected by a 32A Type B MCB to BS(EN)60898, and BS7671 Amendment 2 (which applied at the time) stated that 1.16 Ohms was the maximum value of Zs for such a circuit when corrected for temperature. Seeing as Zs = Ze + R1+R2, then the Zs here when calculated comes to 0.11 + 1.15 = 1.26 Ohm. Oh dear. It seems then that this circuit has a problem because in the event of a fault the breaker may not operate in a timely fashion as the impedance is too high. That said, we know he’s signed this installation off as being compliant, so how did he manage that? Well, look to the right and you’ll notice the Zs column for this circuit shows a value of 0.88 Ohm. Yes folks, in defiance of physics, this circuit has reduced it’s impedance by 0.27 Ohm when Ze has been added to R1+R2. How has this happened? I’ve no idea, but if he truly can make impedances diminish when they’re added together then I’d say he could make a fortune in the semiconductor industry rather than wasting his time on domestic electrics.

Now, although a measured Zs may be lower from the calculation because of parallel earth paths, the problem nonetheless remains on his dead-test results and those ring numbers being too high to be certifiable.

You’ll notice odd numbers apply to other circuits too. Circuit 1 has 0.11 + 0.95 reducing measured at 0.92 Ohm while circuit two goes the other way and sees 0.11 + 0.71 coming to a whopping 1.26 Ohm. Circuit 3 is also high with 0.11 + 0.45 somehow measuring 0.96 Ohm. In fact, all the remaining circuits have a Zs which lands up or down well outside of the maths, so something’s wrong somewhere, either with his Ze, his R1+R2 measurements, his test equipment or his testing method.

While we’re here, let’s also question why no readings appear to have been taken for line-neutral insulation resistance. Remember, this is a complete post-fire refurb so all conductors should have been tested to ensure they weren’t fire or water damaged before this electrical installation was recommissioned.

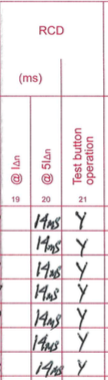

Finally we have the RCD times, and again, why are there no values for the 1x test? As for the 5x test, the same value has been written for all circuits even though two RCD’s are fitted. While it’s not inconceivable that both could give the same 14ms reaction time, I imagine only one has been tested or this number has just been made up and applied to both RCD's. Even the lighting circuit which wasn't on an RCD has this 14mS value recorded!

I found one of the RCD's to be non-operational but as I don't have reliable data on this cert to show it was ever properly tested, then I don't know if it came as faulty from the manufacturer or if it has become faulty over time.

Somewhat bizzarely, the builder has received an alternative certificate from this installer. It has the same certificate number and details, but the Schedule of Inspections is dated earlier at 14/05/13 which matches that inspection sticker date, and there are two Schedules of Test Results...

Apologies for the image quality, but the builder had been given a poorly scanned copy for his records so this is as good as he got. The detail on this first schedule is still nonsense with all the same mistakes as before, but the numbers are completely different now and there are just ticks where there should be Zs values. Also, under the polarity column there appear to be insulation resistance readings.

The second Schedule of Test Results is even more odd. As there's only one consumer unit, I'm not sure why there are two schedules anyway, but the circuit layout on each is different. Maybe one schedule was before he did the work, i.e. the original CU, and the other relates to afterwards, but both are wrong, neither are clear as to which should be current, and you wouldn't include a schedule for a defunct consumer unit on a new certificate because it'll have been superceded by the new results relating to the replacement board. But look at the layout of this second schedule...

...it's just bizarre! What's with all the friggin' ticks? Polarity and Test Button Operation are the only tickbox columns, so what's he doing ticking the boxes used for recording test result values?

Okay, so maybe he's just used this sheet as a checklist while he performs the work. I get that. I'm old school and I still use a clipboard and pencil out on site myself. I did try the iPad, giving iCertify a whirl for a while, but it was a frustrating experience which slowed me down. Those pencil-filled sheets of mine are however nothing more than an aide-mémoire which I use when back at base to create a proper computer generated certificate. I'd never submit my scribblings as part of the final paperwork. It even says on my forms "not to be accepted as certification if handwritten" just to ensure nobody finding it will assume it's part of the final paperwork. Whatever the above is, it should never have been presented as part of the certification for the job and there shouldn't be differences between the paperwork received by the builder and that given to the homeowner under the same reference number.

So there we have it. A NAPIT member with a shockingly lazy approach to his physical installation and his paperwork. But, believe it or not, Things. Get. Worse.

He didn’t notify the work to Local Authority Building Control as required by Part-P of the Building Regulations which is a violation of his NAPIT membership. New circuits, work over £250 in value and the change of consumer unit are all notifiable under NAPITs T's and C's so their six-year workmanship warranty can cover the installation and NAPIT can inform LABC of what's taken place. The installer's failure to notify NAPIT leaves the homeowner without warranty for the botched work as well as leaving her liable for any action the Local Authority may wish to take if they get wind of the missing Part-P. If she wishes to sell the property, which is her plan in the long term, then that missing paperwork could become a real headache. In the short term though, she's sleeping uneasily at night knowing poor quality workmanship and materials mean a decrease in electrical safety and an increase in electrical fire risk. It will cost hundreds to put all this right, but it was an insurance job and shouldn't be costing her a penny.

Personally I believe NAPIT have a duty of care in this case. It’s not the homeowner’s fault that the installer didn’t notify the work. How was she to know? As far as she was concerned, her insurance company appointed the builder and the builder appointed the sparky, reassured as he perhaps was that this installer was a NAPIT member and could be trusted to perform a professional job. If an insurance company and/or builder are project managing the repairs and they subbie out the electrics to someone who is actually accredited, then how is the homeowner to know they’ll be bitten on the arse? Of course, the insurance company and builder also had a duty of care to ensure the work was being completed to the right standard and that the paperwork was submitted correctly, so they may also find themselves in hot water in the event of an incident, accident or a legal claim to cover the cost of making good.

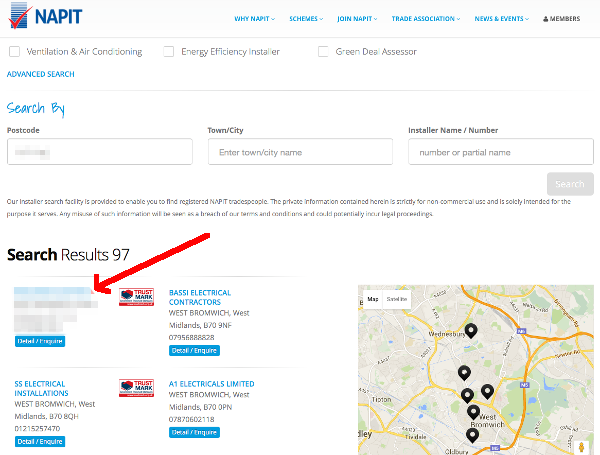

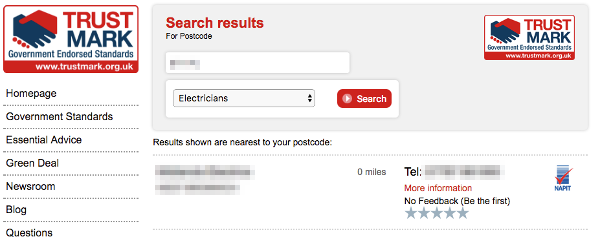

On this installer's website, at the time of writing, he not only states he is a member of NAPIT but also of TrustMark, although I’ve found no evidence that such is the case and he certainly does not appear in a member look-up on the TrustMark website. In fact, he doesn't appear in a look-up on NAPIT's website either. Upon enquiry, NAPIT tell me his membership is currently "on-hold", although I don't know if that's because of other complaints, a failed assessment visit or simply non payment of fees.

So, on behalf of my client, I made a formal complaint to NAPIT as well as notifying TrustMark. As a member of these organisations myself, I go to some effort to maintain the standard of work they require and I can't stand idly by while this guy blags membership but puts in such a poor performance. I’m pleased to report that NAPIT reacted quickly and positively by sending an inspector to meet me on site to view the issues and obtain further photographic evidence.

As I said to the NAPIT inspector, what worries me is that we’ve all seen bad electrical installations, however they’re normally dodgy DIY affairs or cash-in-hand friend-of-a-friend deals where nothing is official and you take the risks for a cheap or quick job. In this case the installer may not have notified the work, but he did provide a BS7671 Electrical Installation Certificate with his signature on it which puts the legal liability for the ongoing electrical safety of the installation onto his shoulders. He even placed a sticker on the CU proudly announcing his company as the installer. Why would he admit to work that is this bad unless he really doesn’t understand how bad it is? The real concern here is that this guy may actually think he’s a good installer. He doesn’t realise just how poor his installation work and his paperwork really are, and one day that may come to bite him on the pants but an unsuspecting customer who hired him in good faith might be dead by then.

In the meantime, the fight is on for the homeowner to have things put right speedily and hopefully at no cost to herself. So far, both NAPIT and TrustMark have each launched investigations into this case. TrustMark tell me this installer was never a member of their scheme and they are contacting him regarding his misuse of their logos. NAPIT are contacting the installer for his response to the issues raised and the photographs taken by their inspector.

The homeowner has also been in contact with both her insurance company and the builder who turned up the alternative certificate paperwork, and it appears a surveyor is now asking questions from that end. So far though, there's still no sign of a building notice turning up.

We'll see where it goes and if anyone offers to step forward to unbotch the job.

Update: 22/03/16

Well, here we are over seven weeks since my initial complaint. So far the following has happened...

TrustMark: Nothing has been heard since they said they would investigate on 9th February.

NAPIT: I'm told they are investigating and have spoken with the installer to hear what he has to say. To date no remedial action has been taken and they have stated this will not be covered by their workmanship warranty. More on that once they come back to me with a final conclusion.

As of today, the company that did this work still has an active website showing the TrustMark and NAPIT logos.

The homeowner has been chasing the builder who oversaw the work for more answers but he has apparently been difficult in his responses. When asked this past weekend why no Part-P was submitted, he provided the following response to her via email:

"Having spoken to a qualified NIECIE electrician who is up to date with all the Regs. I asked him about Part P. Part P is only issued if a qualified electrician comes to your house and just renews a light or socket etc. one off item. In your case this did not happen as you had a 70% re-wire. If you doubt my words please contact the NIECIE organisation."

An interesting reply. One wonders why NICEIC, albeit misspelled, are being mentioned when the builder used a NAPIT sparky for the work. Why does he not get the electrician to respond directly or refer the homeowner to NAPIT? Not that it makes any difference; whether NICEIC, NAPIT or any other CPS scheme, the rules of Part-P remain the same and operate pretty much opposite to how he claims as it's those smaller jobs that are often not notifiable. Does this builder really believe Local Authority Building Control are interested in being informed about a change of light fitting or socket outlet but not a large rewire? Like you'd need planning permission when you buy a new Homebase light fitting for your living room, but Building Control aren't interested if you're having your house rewired or new circuits installed as part of major building work! I don't believe any builder is this stupid as they just wouldn't last long, so this must be flannel to try and get himself out of a tricky position. My response to the homeowner:

Hi ****.

I'm sorry to hear that you're still getting incorrect advice from builders operating out there who apparently misunderstand the requirements of the Building Regulations.

Regardless of the hearsay from an unnamed electrician registered with "NIECIE", if you check with the (correctly spelled) NICEIC Competent Persons Scheme on 0843 596 2454 you will find them confirming Part P applies to the following:

The installation of new circuits (which applies here);

The installation of a new or replacement consumer unit (which applies here);

The installation of any electrical work in a room containing a bath or a shower (which applies here);

and, possibly at the time, the installation of electrical work in a kitchen (although work in kitchens was derated as not-notifiable in 2013).

You can also check this with any other CPS scheme such as NAPIT on 0345 543 0330, Stroma on 01977 665420, Elecsa on 0333 321 8220 or any others you wish to seek advice from.

You can also contact Stratford-Upon-Avon Council Building Control on 01789 267 575 who will take an interest in any building work where adherence with the Building Regulations has not been complied with.

Although you may call any or all of the above numbers, this information can be confirmed with a quick search online. The following websites will back up what I have said:

The Institute of Engineering and Technology (responsible for BS7671, The Wiring Regulations): http://electrical.theiet.org/building-regulations/part-p/faqs.cfm

The Electrical Safety First charity:

http://www.electricalsafetyfirst.org.uk/guides-and-advice/building-regulations/england/

The Electrical Competent Persons register:

http://www.electricalcompetentperson.co.uk/Regulations-Explained

Or, as your builder suggests, the NICEIC:

https://www.niceic.com/Niceic.com/media/Schemes/NICEIC-Part-P-Updated-Factsheet.pdf

The Part-P document is itself available for download from the Government Planning Portal should there be any doubt as to how to adhere to its requirements:

http://www.planningportal.gov.uk/uploads/br/BR_PDF_AD_P_2013.pdf

Please feel free to appraise your builder of this information and to advise him to refrain from seeking advice or installation work on electrics from people who don't seem to know the fundamentals.

Incidentally, I meet with NAPIT in two weeks for an annual assessment. I'll be mentioning your case and the fact that, to date, there appears to be little progress. Maybe something will have happened by then, but I doubt it will be to our satisfaction!

Kind regards,

David.

Update 22/05/16

As the end of April marked three months since I raised my concerns with NAPIT, I decided to check in to see what was happening. Imagine my surprise then when I looked up this rogue installer on the NAPIT website to find his accreditation was no longer on-hold and he was once again showing as a full-scope member, but this time with legitimate TrustMark membership to boot!

Shocked?? Why, I nearly dropped my gin & tonic!

NAPIT: All is forgiven!

Oh, and the same for TrustMark who now proudly list him as one of theirs. How disappointing.

When asked for an explanation, this is what NAPIT came back with…

"Mr Savery

My apologies for the delay in providing you with an update on this matter.

We have carried out an internal investigation on our Member, and advised him of the outcome. He is aware of what he must do to maintain his membership and we will monitoring him closely to ensure he remains compliant.

Whilst I appreciate that this is not the response that you might want, we are not at liberty to provide a more detailed response on this matter. The reason for this, as I’m sure you can appreciate as a Member of NAPIT, is the requirement to maintain confidentiality between our Member and ourselves, and not to provide such information to third parties.

As I explained to you in previous correspondence, as the customer would not allow the Member back to rectify the work, we would be unable to assist any further with our Complaints process.

The customer would need to seek legal advice regarding this matter."

Oh dear. How very woolly. They apparently performed a thorough investigation and in the end all was forgiven. Worse in fact, as they not only let him back in as a full scope member, but they told him he could legitimately use the TrustMark logo if he simply forked over sixty quid. As for them saying the customer wouldn't allow him back to rectify the problems, it was me who advised her that it would be unwise to let this bodger back onto her property. To my knowledge, NAPIT never even asked her.

So, let’s just recap on what they should have been able to pin on this wanker shall we?

He broke the law (Sale of Goods Act 1979 - since updated to the Consumer Rights Act in 2015, but the crime took place in 2013), by installing non-fire rated downlights throughout the house but listing and charging for fire rated models on the invoice.

He broke the law (Electricity at Work Regulations), multiple violations within Regulations 3, 4, 5, 7, 8 and 16 from my quick thumb-through. Although a domestic property, EAWR applies as this was his place of work while he was contracted to perform the remedial work.

He broke the law by violating the Building Regulations under Part-B (fire safety) and Part-P (Electrical Safety) leaving the homeowner with the risk of the Local Authority issuing an enforcement notice or other legal action against her if they get wind of non-compliant work having been performed at the property. Oh, and the risk of death by electrical fire.

He falsely claimed to be a member of TrustMark. He was not, and had never been a member according to TrustMark, at least not until NAPIT allowed him to join after their investigation. He must have known he wasn’t a TrustMark member, so unless he really is monumentally stupid, then he could only have been acting fraudulently by claiming association and displaying their logo.

He violated NAPIT’s own terms and conditions of membership. You know, the stuff that says you must notify a job if it costs over £250 and/or involves certain work such as new circuits, a new consumer unit, electrical work in a special location, all of which applies here.

His ‘certificate’ paperwork is demonstrably nonsense, and the same cert reference was used for two different, but equally bizarre and inaccurate certificates provided to the builder and the homeowner. He clearly fails to meet the definition of a competent person as required by the wiring regulations and by NAPIT's terms of membership.

His poor installation work violated multiple Wiring Regulations with improper circuit protection, improper junctioning, undersized cabling, lack of strain relief, lack of division of circuits, exposed cores, improper paperwork, incorrect labelling etc., all to the detriment of the ongoing electrical safety at the property.

He, quite clearly, doesn't know what the fuck he's doing.

It's not like my complaint was about just one aspect of his work. This is, from what I can see, a shit-list of pretty much everything he could possibly have done wrong. I mean, short of being caught defecating into the homeowner’s favourite flowerpot, poisoning her cat or stealing from her purse, there really wasn’t anything else he could have cocked-up on this job. As far as cocking-up a job goes, the cock doesn’t get much more ‘up’ than what I've listed above.

How do NAPIT believe that he is now fit for purpose, and that with a bit of close monitoring they can assure the public this installer isn’t going to kill someone or burn their house down? Well, unfortunately I can’t answer that, because despite being the complainant and acting directly on behalf of, and with the consent of his victim, the NAPIT internal investigation procedure is confidential, so neither victim nor complainant are privy to the findings.

What a load of shite!

Okay, you may say, maybe this company isn't a one-man-band, and all this was down to a rogue installer who they've now kicked out! But no, that doesn't wash because the company should have had a qualified supervisor overseeing the work and signing off the paperwork. Besides, although a company with the same name is registered with Companies House, they're based in Leicester and NAPIT list this guy at a residential address in Birmingham. He's not operating as a limited company, so is probably a sole trader, therefore the buck does indeed stop with him. There is no possible excuse for things to have been this bad.

So, where do we all go from here?

TrustMark

Now, I don’t blame TrustMark in any way for this debacle. Mr Dodgy wasn’t a member of theirs, he just claimed to be one. TrustMark don’t vet their members, they rely on the CPS operators to check that the additional requirements of TrustMark are being met by those who are registered. All that said however, as far as I know TrustMark ordered this guy to stop using their logo fraudulently but it remained on his website until NAPIT eventually took the sixty pieces of silver it costs to register legitimately. I can’t really confirm TrustMark did anything though, because there was no feedback to my complaint other than lip-service when it was initially made. Technically, being a member of TrustMark now should help any of his future victims who may feel they’ve been short changed (or short circuited) by having an extra avenue of complaint, so in that respect his new membership with them is a good thing, but did TrustMark do enough to protect their brand and prevent it being devalued by someone who wasn’t entitled to use it and is now using it with NAPIT’s blessing? I’m not convinced. If someone this bad can get onto the TrustMark scheme, and if formal complaints are not rigourously acted upon by those who administer the schemes, then what’s the bloody point?

NAPIT

It’s a damn shame because I really liked NAPIT and I had held them in high esteem, but it turns out their six year workmanship warranty isn’t as good as I believed. That’s my fault for never really looking into it more, perhaps because I've never had to, but if you read the T&C’s then you’ll find their warranty only applies if the installer:

a) notified the work through NAPIT, and

b) is now either dead or out of business

So, in this case it’s down to Mr Dodgy to go back and put things right, assuming the homeowner will let him, but to my knowledge NAPIT haven’t asked him to do so, nor have they requested he refund any costs or even asked him to apologise to her. Any remedial action or refund will have to be performed by the homeowner through legal channels at her own effort and expense. She doesn’t even have anything from NAPIT’s investigation to show what concerns or conclusions they may have had, or how the installer responded to the claims against him, because their findings are "confidential".

One of NAPIT’s primary roles is to assess me and my business to make sure I’m not working outside of my qualifications and experience, to ensure I hold valid PI and PL insurance, to test my general electrical knowledge, verify my certificate paperwork is correct, inspect my tool-work, check my test equipment is being maintained and to ensure my policies & procedures are fit for purpose. But now that this has happened, who are they to judge my business practices? Who are they to check my complaints file and procedures when their own complaints procedure results in a dead-end under ‘confidentiality’ bullshit? Who are they to pass or fail my certificates and installation work when standards as low as we’ve seen here are considered acceptable for a full-scope member? Who are they to require me to pay to enrol customers onto their warranty scheme when it means nothing for my customers unless I happen to do a bad job and then get run over by a bus?

Insult to injury: NAPIT now list this fella as being suitable for EICR (condition reporting).

Would you trust this person to pass judgement on whether your electrical

installation is safe or not? Does he know what he's looking at? Does he know how

to interpret test results? Can he be trusted if he claims remedial work is needed?

Can he be trusted to perform work to a safe standard?

Tedious though it is, I’m going to bring Electricity at Work (1989) Regulation 29 into this as it states “..it shall be a defence for any person to prove that he took all reasonable steps and exercised all due diligence to avoid the commission of that offence.” In other words, if an installer ends up in court for causing an electrical incident or accident then they are guilty unless they can prove their innocence. If they can demonstrate compliance with the Building Regulations and Wiring Regulations, then that works in their defence. If there is an incident at this particular property and the long arm of the law gets involved, then this installer, the one now rubber-stamped by NAPIT as being an OK-guy, will very likely be unable to get around Regulation 29 going by what we’ve seen. Any incidents at sites subsequent to NAPIT reinstating him may well see them now also dragged into the dock too as they had the chance to ice him, but instead gave him the green light to keep calm and carry on.

As the last sparky to work on this particular installation it was my duty to report the issues, otherwise I could be held culpable in some way should there have been an electrical incident or accident here in the future. Seeing how bad things were, not reporting it would have made me complicit by my silence under Regulation 29. I might be able to sleep at night knowing that I now have the ‘I told you so’ line of defence, but that doesn’t help the homeowner who has to sleep among sub-par electrics and with the nightmares from the electrical fire she and her kids previously experienced.

So, knowing from all of the above that this installer appears to have acted fraudulently, in no way could have met the requirements of a ‘skilled’ person as defined in BS7671, cannot actually be properly qualified for electrical work (as if he was then both his toolwork and paperwork wouldn’t be this bad), and not knowing what NAPIT found in their investigation, I have to hope that they really had a legitimate reason for allowing him back into the fold, but the only one I can think of would be if this business has since appointed a qualified supervisor who has proven s/he knows their onions and can steer subordinate installers away from making mistakes. Seems unlikely if this is a one-man-band sole trader though.

I certainly hope it is something like that and I trust they didn't let him back in for just financial reasons. I mean, kicking out an installer deprives a CPS of a revenue stream, one which may be taken up by a rival CPS if they’re caught dozing and let this guy on board, but surely NAPIT weren’t solely worried about losing income from one iffy installer?

Surely..?

The huge shit sandwich...

Where does this leave me and my client? Well, she's largely on her own and left to argue with an unhelpful builder, a sparky who is off-the-hook and an insurance company who don't seem to want to know. Legal action is her only route and I will provide whatever assistance I can to aid her with that if she choses to accept the risk, expense and stress involved.

As for myself, I have had a website full of bold statements about how my potential customers can be assured of quality because I’m accredited with NAPIT who provide a six year workmanship warranty on my work and how my being registered with TrustMark should give my clients extra bit of peace of mind. I’ve been banging on to customers for years about this stuff, and frankly it makes me look a little silly now. So, it’s time to put my money where my mouth (and my old fashioned principles of doing a job without ripping off a customer) is by quitting both organisations.

Now, both NAPIT and TrustMark may say I’m just throwing my toys out of the pram; a kneejerk reaction if you will; but I don’t take this lightly, and it’s going to hit me financially. Eradicating their logos from my vehicles, website, business cards, stationery, labels and advertising all costs time and money. Besides that, my PI and PL insurance is through NAPIT, and I have to arrange to transfer to another CPS in order to continue offering a seamless service to my clients.

In the end though, it’s a simple enough business decision. As a legitimate electrical installer it’s bad enough that I sometimes lose business to the cash-in-hand crowd who can undercut me because they don’t have all the assurances I offer. Losing business to non-accredited cowboys is always going to happen, and I accept that,.... but... there has always been a line in the sand between me and a dodgy installer. The dodgy guy may think he’s good at electrical work, but he knows he doesn’t hold relevant qualifications, doesn’t have the expensive test equipment, is not accredited, only works for cash and without warranties, certificates, planning permission or anything else that could trace him back to a moody job. His customers may also know and accept that because they just want something cheap that works and will never look closely enough to see what corners have been cut. Here however, the bad competition has been legitimised and that is what is ultimately unforgivable from a business perspective. This installer's membership was in suspension at the time the complaint was made, but now he's back in operation, in competition with trustworthy installers in this area, backed by NAPIT, providing reassurance through TrustMark, and we’re supposed to believe the wrist-slapping he received, if he even received as much as that, has somehow raised his skills to a level where this cannot happen again.

That’s not so bad, you might say, the next time he screws up NAPIT can come down on him like a ton of bricks and the client has a further avenue of complaint via TrustMark. Well whoop-de-fucking-doo. The trouble is, by then someone else may have a house full of cack-handed electrical work that NAPIT won’t put right. Or a fire engine parked outside. Or an ambulance. How are either NAPIT or TrustMark going to make good when a family of five have been burned to death?

Even if a decent qualified supervisor has been appointed to work with this installer, it doesn't change the fact that the damage has been done for my client, and no word of rectification, recompense or apology has been forthcoming, or was required as a condition of his membership being reinstated.

Despite the aforementioned effort and expense, I have no choice but to divorce myself from these organisations. It is absolutely not acceptable that raising an official complaint regarding someone this bad has the result that they are simply legitimised as credible competition with seemingly no consequences, no explanation and no requirement for them to un-cock what they have cocked up. It makes a mockery of competent person schemes and undermines the aims of organisations like TrustMark. Cowboy tradespeople are a real fear for the public, so arming one with valid accreditations doesn't help those of us who strive to maintain standards.

With my confidence in NAPIT now shot, I have moved to NICEIC as the eagle-eyed (as opposed to those whose eyes are glazing over by this point) may have noticed from the rebranding all over this website and the sanitising of NAPIT logos. Are NICEIC any better? Well, they carry a reputation, and their entry requirements are tougher, for example a one-man-band has to have had at least two years in business before he can join, but only time will tell if they prove more effective at handling complaints should I come across a rogue installer on their watch... and I'm sure they're out there.

To be fair to NAPIT, maybe they know something I don't, after all I do only have half the story here, but all of the above adds up to quite a long list of wrongs, and their secrecy regarding the outcome of their investigation doesn't convince me that all issues have been addressed and they're now firmly on top of things. Unlikely as it may well be, if NAPIT did keep the iffy installer on their books just for the income stream, they have now lost my ongoing membership money, along with my TrustMark fee, professional indemnity insurance, public liability insurance, electrical wholesale account and Part-P notification fees. If NAPIT and TrustMark want to legitimise installers as bad as this, they can do so to the detriment of their own reputations and tainting of their own brands, but I shall keep my reputation safely intact by disassociation.

My registrations with NAPIT and TrustMark expire at the end of 2016, so between now and December I will still show up on their searches. My branding won't reflect that however.

Van stickers removed. The end of an era!

Van stickers removed. The end of an era!

Were my expectations of a favourable outcome unrealistic? Maybe. But feedback I've received from other electricians has shown some shock and surprise that it went nowhere even though their perception seems to be that the CPS model is full of bluster, quick to make promises and to take the membership money, slow to react when something goes bad. I get the impression most other sparkies wouldn't have bothered raising a complaint in the first place, which is unfortunate for the industry and the public.

I have to wonder, if it's this hard for me as a professional to bring a rogue installer to book, even by presenting all of the above evidence, then how tough is it for the public to see through a successful complaint? Joe Average doesn't know enough about the job or the industry to be able to fight his corner; and that's why he installed someone whom he thought was a professional in the first place!

My advice for seeking an accredited electrician is to check this website to ensure the installer you're planning to use is registered with any bodies they claim to be associated with, but that in itself is no guarantee of quality.

Postscript, August 2017: back on TrustMark.

Eight months after coming off the TrustMark database, I am now back on it. Why? Well, simply because I joined the Electrical Contractors Association in the summer. When applying to join, other ECA members in the geographic region are canvassed for their objections, so those who have a reputation that is known in the area, good or bad, can be processed by their peers accordingly. Compliance with ECA operating guidelines ticks the boxes that TrustMark expects contractors to abide by and so grants me free entry to their database.

In short, TrustMark trust the ECA not to let anyone become a member unless they make the grade, so I am a member by association this time rather than by paying extra for membership via a CPS scheme.

Not that any of this changes what was written above. I still believe TrustMark are too reliant on weak CPS schemes to enforce standards. There's little I can do about it all though, except to maintain my own standards and publish information to try and prevent people parting with their hard earned cash for shoddy jobs or bad advice.